Introduction to Beverage Packaging and its Importance

Welcome to the exciting world of beverage packaging, where innovation and sustainability are shaping the future of how we enjoy our favorite drinks. From refreshing sodas to nutritious juices, the way beverages are packaged plays a crucial role in their journey from production to consumption. In this blog post, we will explore the latest trends and innovations in filling machinery that are revolutionizing the beverage packaging industry. So grab your drink of choice and let’s dive into the dynamic world of packaging technology!

Current Trends in Beverage Packaging

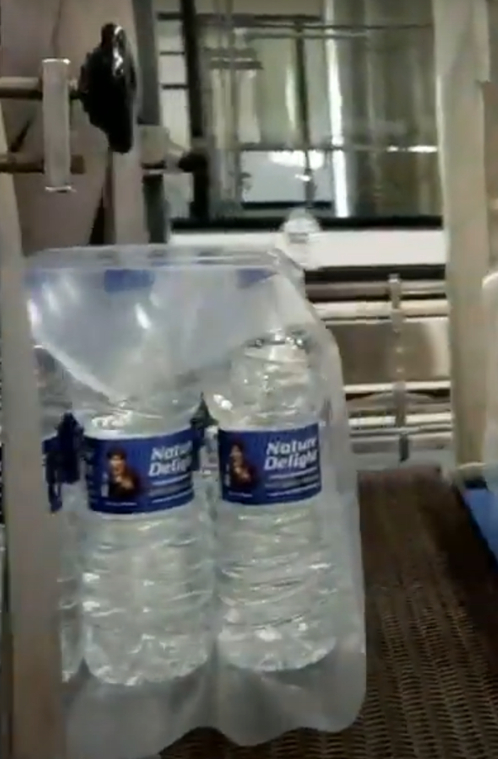

As the beverage industry continues to evolve, so do the trends in packaging. One notable trend is the rise of convenient single-serve options like cans and pouches, catering to on-the-go consumers looking for grab-and-go solutions. Another popular trend is the use of minimalist design and bold colors to attract attention on crowded shelves.

Brands are also investing in interactive packaging techniques such as QR codes and augmented reality to engage customers beyond just their product. Furthermore, personalization in packaging through customization or limited-edition releases has been gaining traction, allowing companies to create unique experiences for their consumers.

Sustainability remains a key focus with more brands shifting towards recyclable materials and reducing plastic usage. Plant-based alternatives, compostable packaging, and refillable containers are becoming more prevalent as eco-conscious consumers drive demand for greener options.

Innovations like smart labels that provide real-time information on freshness or temperature control are shaping the future of beverage packaging. With technology playing a significant role, we can expect even more exciting developments ahead in this ever-evolving industry.

The Rise of Sustainable and Eco-Friendly Packaging

As consumers become more environmentally conscious, the demand for sustainable and eco-friendly packaging in the beverage industry is on the rise. Brands are shifting towards materials that are recyclable, biodegradable, or made from renewable resources to reduce their carbon footprint.

Innovations such as plant-based plastics, compostable packaging, and reusable containers are gaining popularity among companies looking to appeal to eco-conscious consumers. This shift not only benefits the environment but also helps businesses differentiate themselves in a competitive market.

By embracing sustainable packaging practices, beverage manufacturers can not only meet consumer demands but also contribute to a healthier planet for future generations. The trend towards sustainability is reshaping the industry’s approach to packaging design and manufacturing processes, paving the way for a greener future in beverage packaging.

Innovative Filling Machinery for Beverages

Innovative filling machinery is revolutionizing the beverage packaging industry. These cutting-edge machines are designed to enhance efficiency, accuracy, and speed in filling beverages into containers. From high-speed rotary fillers to advanced volumetric fillers, the options for beverage manufacturers are diverse and tailored to meet specific needs.

One of the key advancements in filling machinery is the integration of IoT technology. This allows for real-time monitoring and adjustments, ensuring consistent fill levels and reducing product wastage. Additionally, new materials and designs have improved hygiene standards, making cleaning and maintenance easier than ever before.

Moreover, automation features such as robotic arms for handling containers and smart sensors for detecting inconsistencies have further streamlined the filling process. With these innovations, beverage companies can boost productivity while maintaining high quality standards in their products.

Innovative filling machinery is paving the way towards a more efficient and sustainable future for beverage packaging.

Automation and Digitalization in Packaging Processes

Automation and digitalization are revolutionizing the way beverage packaging processes operate. With advanced technologies like robotics and machine learning, companies can streamline their production lines for efficiency and accuracy.

By implementing automated filling machinery, tasks that once required manual labor can now be completed with precision and speed. This not only increases productivity but also reduces the margin of error in packaging.

Digitalization plays a crucial role in monitoring and optimizing packaging processes. Real-time data collection allows manufacturers to analyze performance metrics instantly, leading to proactive decision-making for continuous improvement.

Through automation and digitalization, beverage packaging companies can meet consumer demands more effectively while minimizing waste and maximizing resource utilization. The future of filling machinery lies in embracing these innovative technologies to stay ahead in an ever-evolving industry landscape.

Challenges and Opportunities for the Future of Beverage Packaging

As the beverage packaging industry evolves, new challenges and opportunities arise. One of the key challenges facing the future of beverage packaging is meeting consumer demand for sustainability while maintaining product quality and shelf life. This shift towards eco-friendly solutions presents an opportunity for innovation in materials and processes.

Another challenge is keeping up with rapidly changing consumer preferences and market trends. Brands must adapt quickly to stay relevant and capture audience attention amidst fierce competition. This dynamic landscape also offers opportunities for companies to differentiate themselves through unique packaging designs and functionalities.

Furthermore, technological advancements bring both challenges and opportunities. While automation streamlines production processes, it also requires investments in training employees on new equipment. Embracing digitalization can lead to improved efficiency but may also pose cybersecurity risks that need to be addressed proactively.

In this ever-evolving industry, staying ahead of the curve requires a blend of creativity, adaptability, and foresight to navigate challenges while seizing opportunities for growth and innovation in beverage packaging.

Conclusion: Embracing Change for a More Sustainable Industry

As the beverage packaging industry continues to evolve, embracing change is crucial for creating a more sustainable future. By adopting innovative trends and filling machinery technologies, companies can reduce waste, improve efficiency, and meet the growing demand for eco-friendly solutions. Automation and digitalization are revolutionizing packaging processes, offering opportunities for increased productivity and accuracy.

Challenges may arise along the way, but with a proactive attitude towards innovation and sustainability, the beverage packaging sector can overcome obstacles and thrive in a changing market landscape. By staying ahead of trends and investing in cutting-edge solutions, manufacturers can position themselves as leaders in creating a more environmentally conscious industry.

Embracing change is not just about keeping up with the times; it’s about shaping the future of beverage packaging by prioritizing sustainability and efficiency. With a collective effort from all stakeholders involved, we can work towards building a more sustainable industry that benefits both businesses and our planet. Let’s raise our glasses to a brighter tomorrow for beverage packaging!